PA6-GF30 (P1288)

High-Performance Polyamide 6 for Tough Applications

Technical Specifications

Mechanical Properties

| Tensile Strength | 176 MPa |

| Tensile Modulus | 1373 MPa |

| Flexural Strength | 261 MPa |

| Flexural Modulus | 7462 MPa |

| Izod Impact (23°C) | 16.5 kJ/m² |

| Charpy Impact (23°C) | 11.2 kJ/m² |

| Melting Temperature | 198.4 °C |

| HDT @1.8MPa | 216.8 °C |

| Flammability | UL94 HB |

Processing Guidelines

| Melt Temperature | 250–275 °C |

| Pre-drying | 80–100 °C / 4–8h |

| Molding Shrinkage | 0.2–0.6% |

| Water Absorption | 32% (boiled) |

| Density | 1.36 g/cm³ |

| Ash Content | 30% |

Molding Parameters

| Mold Temperature | 80–120 °C |

| Injection Pressure | 70–130 MPa |

| Back Pressure | 7–15 MPa |

| Moisture Sensitivity | <0.2% before molding |

| Nozzle Temperature | 260–270 °C |

| Barrel Temperature | 240–275 °C (profiled) |

Packaging & Pricing

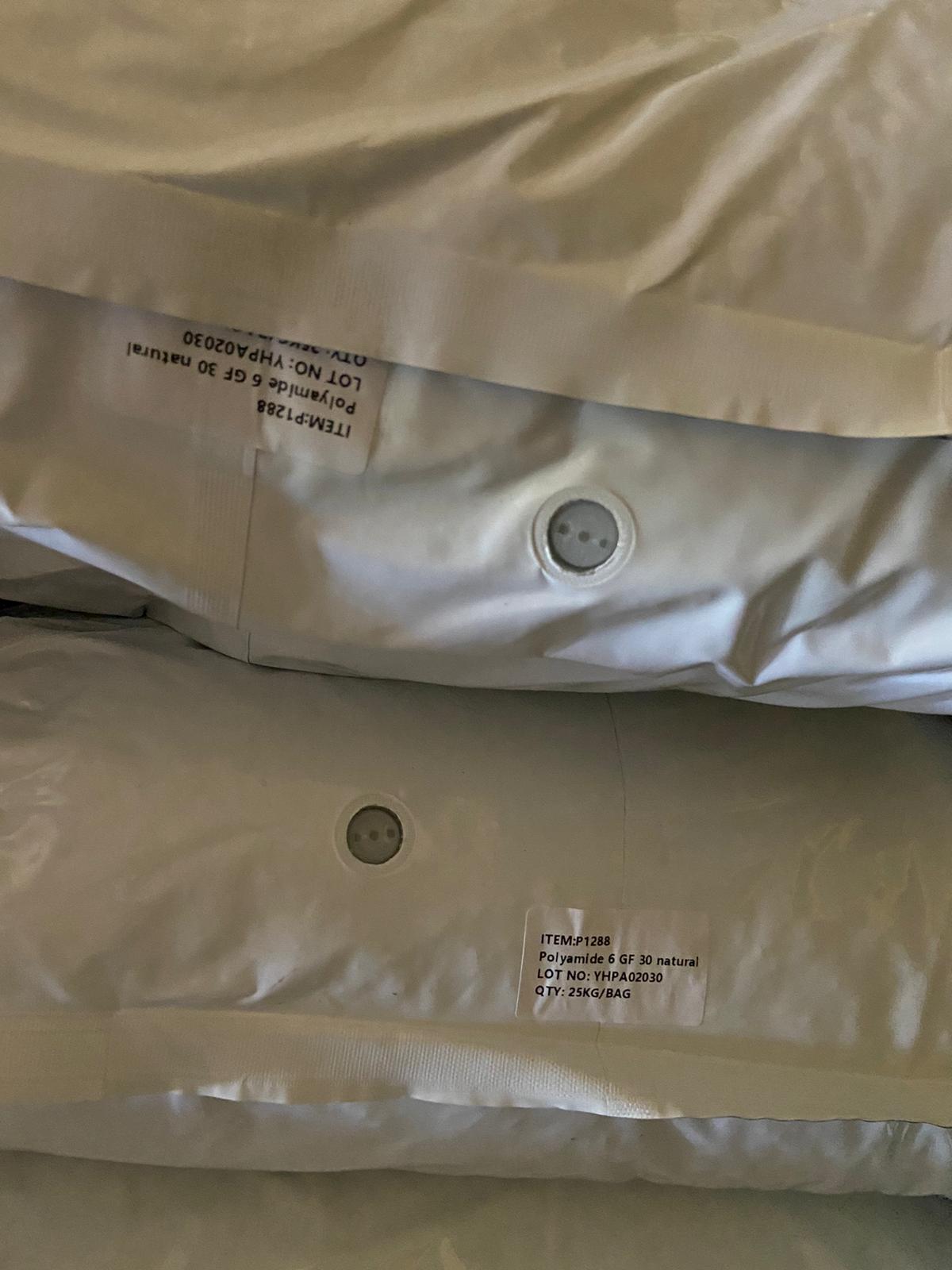

Our PA6-GF30 Natural polyamide is supplied in waterproof, industrial-grade packaging, specifically designed to preserve material integrity during storage and transport.

Current available: 20 metric tons in stock in Bulgaria

Production

Polyamide

Production

Polyamide

Production

Polyamide

Our Product is Suitable For

Automotive Parts

Engine covers, brackets, housings

Industrial Applications

Gear systems, structural components

Electrical Systems

Connectors, relays, casings

Frequently Asked Questions

When stored in a dry, sealed condition, the shelf life exceeds 24 months.

Yes, PA6-GF30 is ideal for insert molding due to its excellent flow and rigidity.

We can develop custom compounds on request, including color, UV, flame-retardants and more.

Yes. We support low MOQs for sampling and testing — just get in touch.